.gif)

|

Cixi Fule Flooding Equipment Co.,Ltd.

|

Precision Brass Turned Components machining parts

| Price: | 0.3~10.0 USD |

| Payment Terms: | T/T,L/C,D/A,D/P |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Precision machining parts

102 SETS OF CNC machines

Skilled and rich experienced staff

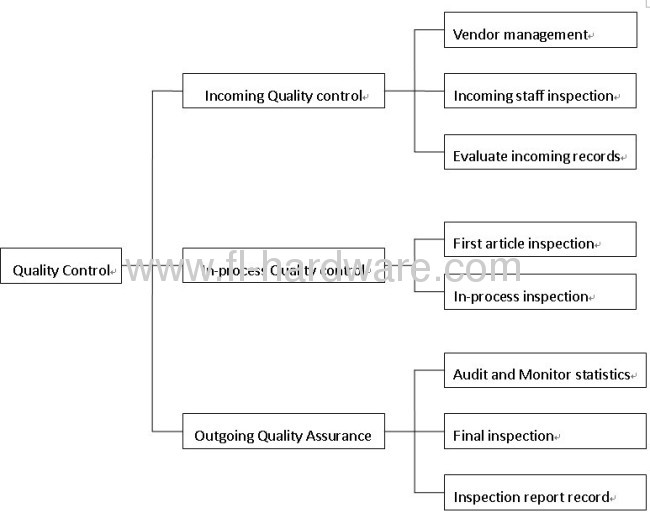

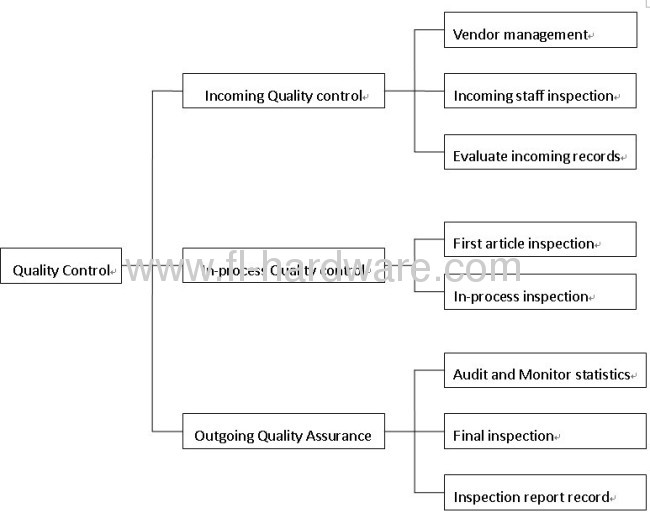

Always Stable quality control

Economic production way

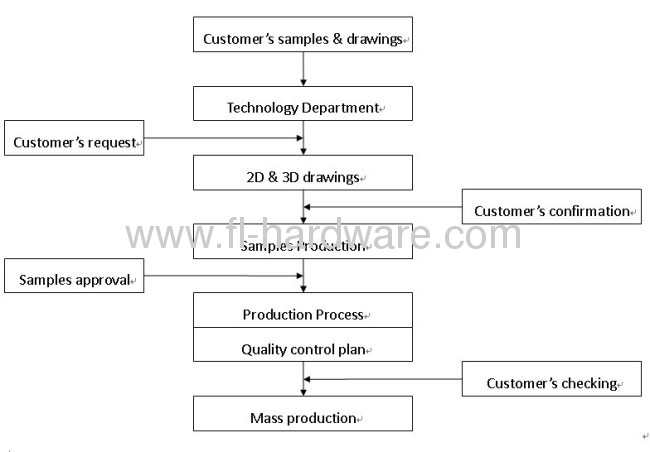

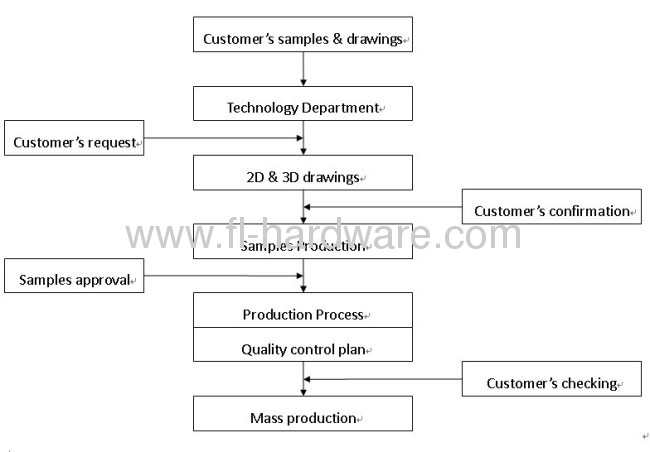

1) Mold design and construction

2) Cast and machine complete includingheat treatment, NDT testing and coatings

3) Materials included but not limitedto: austenitic, martensitic and precipitation hardening stainless steel alloy,tool, high strength steels, aluminum, copper, magnesium and cobalt-based alloy

4) Tolerance: o linear+/-0.1mm per 20mm

5) Straightness: 0.1mm per 20mm

6) Angular: +/-1 degree

7) Surface finish: 3.2mm (125rms)

8) Flatness: 0.1mm per 20mm²

9) Casting grade and class according to MILspecifications, commercial standards 10) Inspecting equipment: spectrometer,X-ray, CMM

We are able to produce customermade precision stamping parts, forging parts , casting parts, CNC machinedparts, mechanical components ,mechanical parts and cnc machining parts and so onfor you.

1) Precision forging, cutting by CNCmachine, Heat-treatment with high quality.

2) Advanced technologies and rigorousQuality control.

3) Very competitive prices and satisfactory Service.

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

Related Search

Precision Brass Turned Components

Brass Machining Parts

Turned Parts

Aluminum Turned Components

Precision Machining

Machining Parts

More>>

.jpg)

.jpg)

.jpg)

.jpg)